In this article, I will examine the Best AI Tools for Digital Twin Simulations, which are changing how industries observe, optimize, and handle physical systems.

These tools use AI, IoT, and real-time analytics to form close approximations of virtual copies and facilitate predictive maintenance, performance optimization, and intelligent, real-time decision-making. Companies in the manufacturing, infrastructure, and industrial sectors are utilizing these tools for enhanced performance and innovation.

What is Digital Twin Simulations AI Tools?

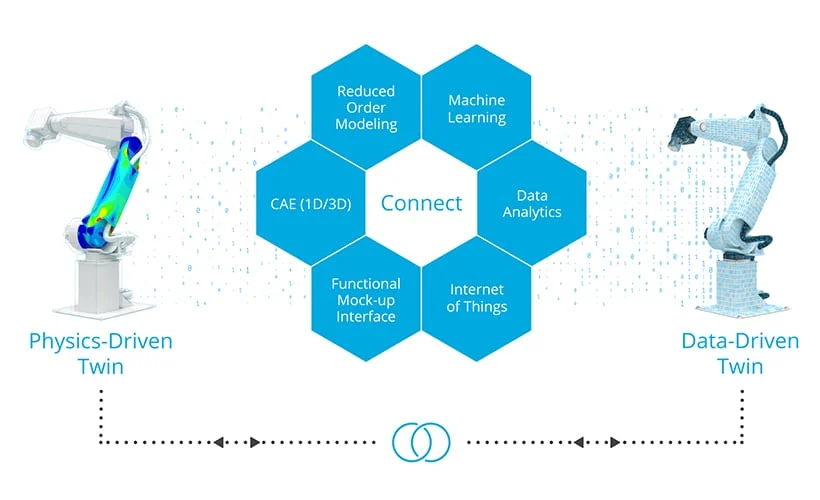

Digital Twin Simulation AI tools form part of a new generation of sophisticated software platforms that leverage real-time data, sensors, and AI algorithms to construct a virtual replica of a system, process, or product, a technology capable of allowing businesses and Engineers.

This technology enables businesses, Engineers, and almost any other sector of activity to simulate, monitor, and optimize virtually any operational process, allowing predictive maintenance, operational optimization, and what-if scenario analysis, thus, avoiding engagement with the physical entity directly.

Thanks to AI, these tools assess enormous data volumes, derive actionable insights, recognize trends, anticipate problems, and recommend timely, precise, and economical solutions. This technology is of great help in the industries of advanced manufacturing, health care, smart cities, and those connected with IoT in general.

Why Use AI Tools for Digital Twin Simulations

Refined Predictive Maintenance – AI uses real-time and historical data to forecast and preemptively detect potential downtimes and equipment failures.

Improved Efficiency – AI systems evaluates numerous scenarios to determine the best strategies for achieving maximum efficiency.

Enhanced Agility – AI offers the potential for rapid assessments on the presumed results of a variable change without need of a physical system experimentation.

Lowered Costs – Costs associated with developing expensive prototypes and real-world trial-and-error processes are minimized due to virtual testing.

Reduced Risks – AI simulations can forecast operational failures and safety hazards to be proactive and lessen risk exposure.

Learning and Enhancing – Continuous AI data assimilation results in a more accurate digital twin and subsequently a more intelligent system.

Planning and Adaptive Innovation – With AI, organizations can easily experiment with new strategies and designs to encourage innovation while keeping current processes uninterrupted.

Key Point & Best AI Tools for Digital Twin Simulations List

| Digital Twin Tool | Key Features / Highlights |

|---|---|

| PTC ThingWorx | Real-time monitoring, predictive analytics, IoT integration, easy app development. |

| Azure Digital Twins | Cloud-based, scalable, supports complex modeling, integrates with Microsoft ecosystem. |

| GE Digital Twin Software | Industrial focus, equipment optimization, predictive maintenance, heavy machinery analytics. |

| Bentley iTwin | Infrastructure digital twins, 3D modeling, data visualization, lifecycle management. |

| IBM Maximo Application Suite | Asset management, AI-driven insights, predictive maintenance, enterprise-level integration. |

| Altair SmartWorks | IoT and simulation integration, AI analytics, customizable digital twin solutions. |

| AVEVA Digital Twin | Industrial operations focus, real-time visualization, predictive and prescriptive insights. |

| Oracle IoT Digital Twin | Cloud-based, IoT connectivity, real-time analytics, integrates with Oracle ecosystem. |

1. PTC ThingWorx

PTC ThingWorx is regarded as one of the finest artificial intelligence programs for Digital Twin simulations as it integrates the Internet of Things (IoT), AI, and real-time analytics all in one place. Its primary advantage is allowing organizations to virtually integrate numerous complex processes and pieces of equipment.

ThingWorx offers a low-code environment to decrease the time needed to design custom digital twin applications to meet particular business requirements.

Apart from digital twin applications, AI-powered analytics also diagnose waste, performance deterioration, and impending outages to streamline processes. This results in cost-cutting, improved efficiency, and accelerated innovation for firms.

PTC ThingWorx Features

- Rapid Application Development: With the help of low-code tools, quickly design and deploy digital twin applications.

- IoT Integration: Connects with IoT devices for real-time monitoring and predictive analytics.

- Advanced Analytics: Evaluates performance and operational optimization through machine learning and AI.

2. Azure Digital Twins

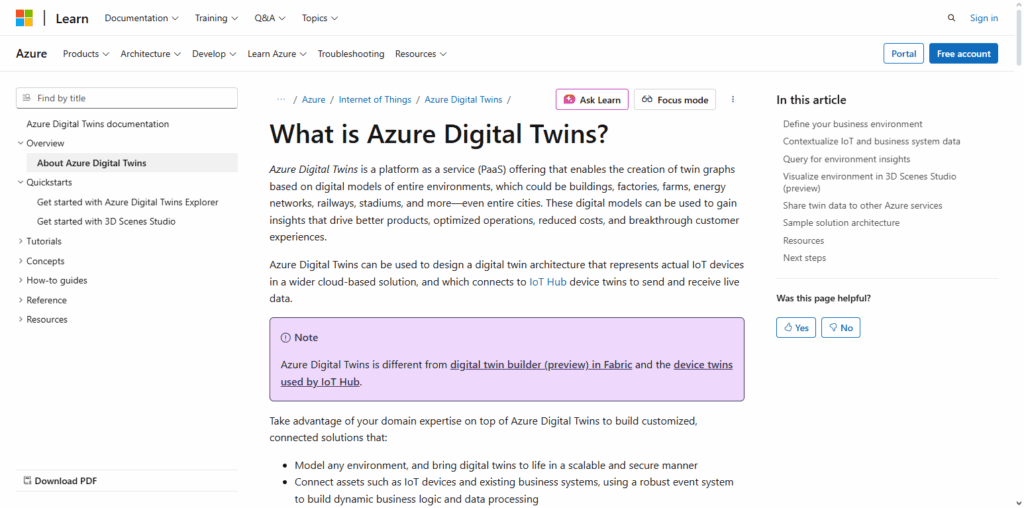

One of the best AI tools for Digital Twin Simulations is Azure Digital Twins. This is due to its advanced cloud infrastructure and capability for scalable modeling of intricate physical settings.

Its primary differentiating feature is the ability to produce tailored digital replicas of actual systems, which allows organizations to run simulations, assess different variables, and fine-tune procedures in real-time.

It utilizes AI and IoT data to generate predictive insights for more informed, efficient decision-making. Its seamless integration into the Microsoft ecosystem enhances its Digital Twin capability. For smart buildings, industrial operations, and extensive IoT deployments, Digital Twins is best for scalability, security, and seamless integration.

Azure Digital Twins Features

- Scalable Digital Modeling: Build in-depth digital models of real-world environments from buildings to large factories.

- Real-Time Insights: Combines operational simulation and predictive capabilities with real-time IoT data.

- Integration with Azure Services: Combines Azure AI, IoT Hub, and analytics services for enhanced simulation capabilities.

3. GE Digital Twin Software

GE Digital Twin Software is an industry leader in Digital Twin Simulations, focusing on industrial and heavy equipment.

The software’s fusion of AI with IoT and advanced analytics enables the construction of precise digital twins of devices and processes, which facilitates predictive maintenance and operational optimization.

GE’s Software Predicts failures and avoids downtime, maximizing asset performance by continuously analyzing real-time sensor data.

Simulated operational scenario analysis aids in efficiency and safety improvement. GE is a trusted partner for smart and data-driven manufacturers and industrial operators in the energy and complex industries, owing to its industry knowledge, advanced analytics, and software.

GE Digital Twin Software Features

- Industrial-Grade Analytics: Analytics tailored to predictive maintenance, heavy machinery, and industrial complex processes.

- Asset Performance Monitoring: Monitors the state and performance of machinery and equipment in real-time.

- AI-Driven Optimization: Uses machine learning to enhance operational efficiency and minimize downtime.

4. Bentley iTwin

Bentley iTwin excels as an AI tool for Digital Twin Simulations. Thankfully, it was specially developed for Digital Twin Simulations in the engineering and infrastructure sector.

One of its best features is the combination of everything design, construction, and operational data into a 3D digital twin.

This allows a real-time, accurate digital twin of a physical asset. Predictive maintenance and performance optimization for complex infrastructures are possible too by the system AI and advanced analytics.

Seamless collaboration, early data-driven issue identification, and problem solving in engineering workflows are possible with flexible cross-functional integration. Infrastructure management in conjunction with modern predictive and AI analytics is possible with Bentley iTwin.

Bentley iTwin Features

- Infrastructure Modeling: Digital twins for civil, structural, and utility infrastructure.

- 3D Visualization: Develops realistic 3D models to design, monitor, and plan for various elements.

- Collaborative Platform: Incorporates co-creation tools while enabling numerous stakeholders to access, revise, and concurrently simulate infrastructure projects.

5. IBM Maximo Application Suite

The IBM Maximo Application Suite is considered to be among the best AI applications for optimizing asset management and operational processes using digital twin simulations.

Maximo’s capability of merging AI, Analytics, and real-time IoT as smart analytical engine digital twins predicting and estimating asset value is remarkable. Maximo’s continuous operational data stream monitoring and analyses facilitates predictive maintenance, downtime reduction, and equipment life extension.

Each individual deployment’s enterprise-class features serve unlimited scaling and facilitate AI-guided operational decision enhancements. Predictive Analytics, automation and visualization triad empower Maximo customers to manage intricate industrial systems, and maximize operational efficiency and automation belt and whittle down expenses.

IBM Maximo Application Suite Features

- Enterprise Asset Management: Dedicated system to track and oversee the management of physical assets.

- Predictive Maintenance: Maintenance of assets with the use of AI and machine learning to prevent system downturns.

- IoT and AI Integration: Connects IoT sensors and applies AI-driven analytics to enhance productivity and workflow.

6. Altair SmartWorks

Altair SmartWorks integrates artificial intelligence with Digital Twin Simulations, uniting IoT, AI, and advanced analytics into one platform. Flexibility and scalability distinguish SmartWorks, as users configure flexible intelligent digital twins that track, assess, and optimize physical systems and processes in real time.

Predictive maintenance, operational efficiency, and scenario testing within SmartWorks facilitate organizational decision-making, as users simulate several outcomes before applying the decision in the real world. The customizable workflows enhance users’ dashboards, allowing for data-driven decision-making across various sectors.

The effective combination of AI, Smart IoT, and advanced simulation technologies, has made Altair SmartWorks invaluable in digital twin innovation.

Altair SmartWorks Features

- IoT Data Aggregation: Gathers and merges data from a multitude of sensors and other devices.

- Simulation-Driven Insights: AI simulations are run to design, assess performance, and optimize products.

- Scalable Cloud Platform: Accommodates the large and real-time remote observation.

7. AVEVA Digital Twin

AVEVA Digital Twin stands out as the premier AI technology for Digital Twin Simulations, particularly for hyper-focused industrial use cases, real-time process optimization, and real-time industrial operations.

Where AVEVA excels is the integration of AI, Internet of Things, and advanced visualization to develop state-of-the-art replicas of intricate systems for predictive maintenance and operational efficiency. Being able to monitor operational performance and evaluate tailoring scenario analyses to solve inefficiencies is pioneered by AVEVA.

Spark-nose controls real-time analytics, self-service dashboards, and decoupled scenario analytics. By connecting engineering with operations and actionable data, AVEVA Digital Twin transforms industries and enables them to do more for less to optimally drive transformation and productivity.

AVEVA Digital Twin Features

- Industrial Operations Focused: Tailored for the activities of the manufacturing, energy, and process industries.

- Predictive Analytics: Proactively predicts and preventing losses and operational inefficiencies by forecasting failure, detecting AI, and anomaly optimization.

- Comprehensive Visualization: Complex operational control and monitoring via a 3D view by interactive dashboards.

8. Oracle IoT Digital Twin

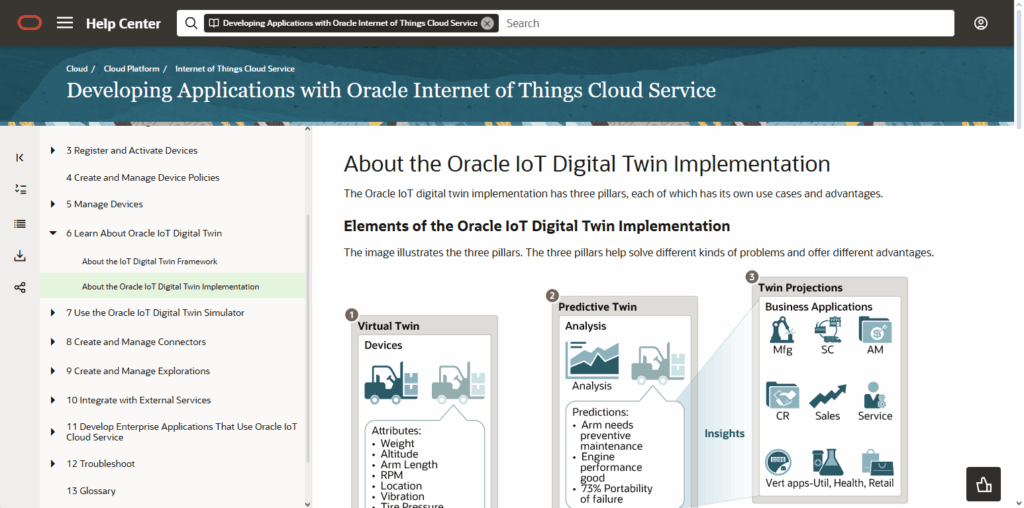

Oracle’s IoT Digital Twin uses advanced AI to provide real time analytics and optimizations for connected assets and processes. Differentiated back in integrading IoT data with AI analytics to formulate actionable Digital Twins.

Oracle’s platform predictive maintenance and operational scenario analytics assist organizations in estimating and reducing downtime. With predictive maintenance and operational scenario analytics, organizations can estimatedowntime and failure forecast.

Mounted cloud scalability, powerful security, and Oracle ecosystem integrations allow extensive cross-industry enterprise deployments. Oracle IoT Digital Twin combines intelligent analytics with real-time monitoring and simulation to provide enterprise customers powerful tools for quick and smart decision-making.

Oracle IoT Digital Twin Features

- Connected IoT Ecosystem: Combines data IoT streams from devices, sensors, and spatial and operational enterprise applications.

- AI-Powered Insights: Generates predictive analytics for anomaly detection and maintenance optimization.

- Cloud-Ready Platform: Offer digital twin simulations in a secured, scalable, and cloud powerful environment.

Conclusion

To conclude, The Best AI Tools for Digital Twin Simulations considerably changed how industries control and fine-tune their operations. Tools like PTC ThingWorx, Azure Digital Twins, and GE Digital Twin Software incorporate AI, IoT, and real-time analytics, and enable predictive maintenance, scenario testing, and improved efficiency.

The use of advanced platforms helps businesses lower operating costs and downtime as well as improve decision-making, all of which fosters innovation and excellence in operations for manufacturing, infrastructure, and other industrial sectors. Using digital twins with AI helps fine-tune complex systems, adapting them to modern demands.

FAQ

Which are the best AI tools for Digital Twin Simulations?

Some of the leading tools include PTC ThingWorx, Azure Digital Twins, GE Digital Twin Software, Bentley iTwin, IBM Maximo Application Suite, Altair SmartWorks, AVEVA Digital Twin, and Oracle IoT Digital Twin.

Which industries benefit the most from these tools?

Manufacturing, infrastructure, energy, smart cities, and industrial operations benefit most by improving efficiency, safety, and cost-effectiveness.

How do these tools improve operational efficiency?

They analyze real-time data, predict potential failures, optimize processes, and allow scenario simulations to make proactive decisions without impacting physical operations.

Are these tools scalable for large enterprises?

Yes, most tools like Azure Digital Twins, IBM Maximo, and Oracle IoT Digital Twin are cloud-based and designed for enterprise-level scalability and multi-site deployments.